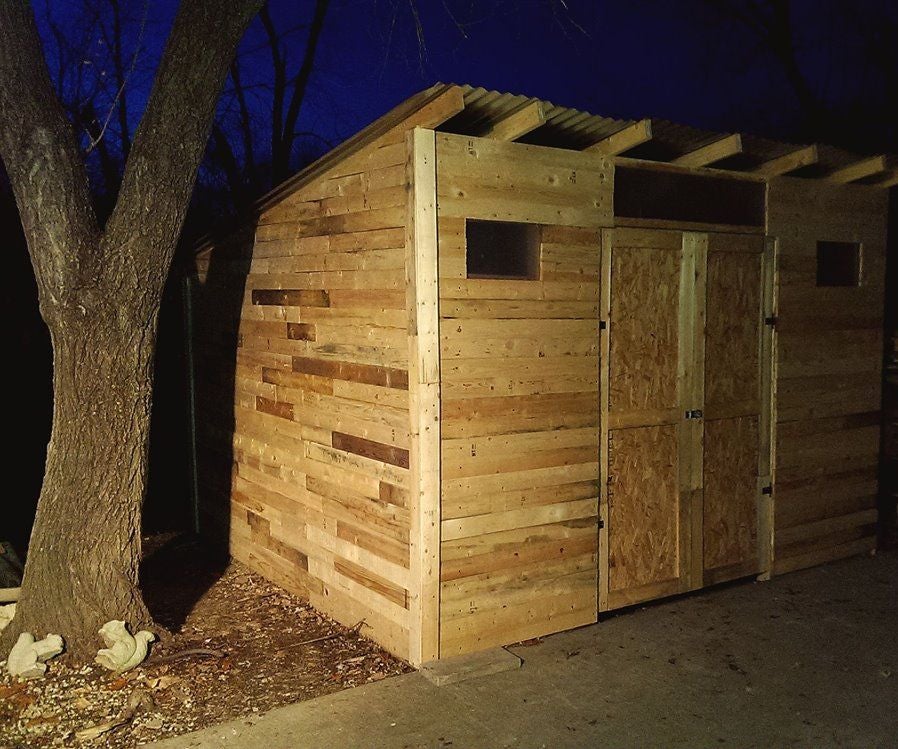

Lean-To Shed Build: Simple Materials, Maximum Results

Dreaming of extra storage space or a charming outdoor workspace without breaking the bank? A lean-to shed offers a fantastic solution, combining practicality with ease of construction. This guide empowers you to build your own, utilizing readily available materials and simple techniques to achieve impressive results. Forget complicated blueprints and expensive contractors; let's get building!

Planning Your Lean-To Shed

Before you even pick up a hammer, meticulous planning prevents costly mistakes down the line. First, choose your location wisely. Consider proximity to existing structures for easy access and potential utility connections. Analyze the terrain; a level base is crucial for stability. Next, determine your shed’s dimensions. Keep it simple: a rectangular shape is easiest to construct. Measure and mark the area clearly. Finally, gather your building materials. This will vary based on your design but generally includes pressure-treated lumber for the frame, plywood or corrugated metal for the walls and roof, and appropriate fasteners.

Essential Tools for Success

Having the right tools at your disposal streamlines the building process. Your arsenal should include a measuring tape, level, post-hole digger or auger (depending on your foundation), saw (circular saw is ideal), hammer, drill, screwdriver bits, and safety glasses. A shovel for grading and leveling the ground will also prove invaluable. Don’t forget to invest in quality work gloves to protect your hands!

Foundation and Framing: Building the Base

A solid foundation is paramount. For a simple lean-to, consider a concrete slab, gravel base, or even pressure-treated lumber laid on compacted earth. Level the ground meticulously before beginning construction. Once your base is secure, erect the frame. Begin by attaching pressure-treated 4x4 posts to the supporting wall of your existing structure (this will form one side of your lean-to). Then, create the opposite side with additional 4x4 posts and connect the top using 2x4 lumber to form the framework. Ensure all corners are square and securely fastened. You can use metal brackets to strengthen the connections.

Roof Construction: Keeping it Simple

Constructing the roof is straightforward for a lean-to design. Use 2x4 rafters, spaced appropriately based on the chosen roofing material's weight specifications, and connect them to the frame. Ensure a sufficient slope to allow for water runoff. You'll likely need to use a speed square to ensure the proper angle on each rafter. Once the rafters are in place, sheathe the roof with your chosen material â€" plywood, corrugated metal sheeting, or even durable tar paper, depending on your budget and aesthetic preferences. Secure the roofing material with appropriate nails or screws.

Walling and Finishing Touches

Depending on your needs, you may choose to enclose the sides of your lean-to. Plywood offers a relatively inexpensive option that you can easily paint or stain to match your existing structure. Corrugated metal sheeting offers exceptional durability and weather resistance. Install the wall sheathing, ensuring a snug fit. Consider adding a door for easy access. For a more professional finish, you can apply trim around the edges, paint, or stain the wood to match your exterior design. Always ensure that all exposed edges are properly sealed with waterproof sealant to protect against rot and water damage.

Essential Considerations

With careful planning, attention to detail, and a little elbow grease, you can transform a simple concept into a practical and aesthetically pleasing lean-to shed. The sense of accomplishment is immeasurable, not to mention the added value and functionality you gain!